Tec-Sieve Products

Accredited to ISO: 9001 Stainless Steel Test Sieve Stainless Steel Woven Wire Mesh Grassland Fence Steel Grating Expanded Metal Aluminium Expanded Mesh Perforated Metal Wedge Wire Filter Elements Stainless Steel Welded Mesh Panels Manganese Steel Crimped Wire Mesh Stainless Steel Rope Mesh Decorative Wire MeshPerforated Metal

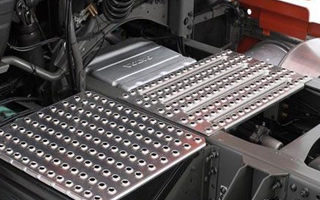

We perforate a wide range of round, square, slotted, decorative and even odd shaped perforations from a numerous metal sheets. The most common percentage of open area is between 30% and 50% although more extreme open areas are available depending on the perforation. Some times the percentage open area has to be kept lower for increased strength and flatness of the perforated metal sheet especially when galvanising.

The maximum sheet thickness, which we can perforate up to, is 25mm, the most common thickness range for balustrade infill, cladding panels is between 1.5mm and 3.0mm although heavier specifications do away with having to frame the sheets with something like edging profile which we also supply.

How to Make Perforated

The sheet is fed to the machine by means of a Roller System Mechanism. The die is preloaded on the machine. On feeding the sheet, the upper section of the machine starts stroking. The sheet is perforated as per the die and is advanced by the amount of the perforated pitch set on the machine, with the next stroke of the slide. This cycle of feeding and perforating continues automatically.

Major Applications: Mining,Chemistry,Agriculture,Architecture,Air and Oil Filters,Screening process for Grain,Drying,Furniture,Hammer Mills, Etc.

Mobile: 008613731374419 WhatsApp: 008613731374419 Wechat: 008613731374419

Copyright © Hebei Tec-Sieve Wire Mesh Products Co., Ltd.